Q: What has buying a titanium bike got to do with the mystical charms of eating the Fugu (Japanese Puffer Fish)?

A: The answer is neither should be rationally contemplated on a budget or without knowing the precise provenance of the raw material and more especially the chef/welder who will ultimately prepare it for you.

Titanium vs Carbon Bikes vs Fugu and Neurotoxins

The Fugu contains fatal neurotoxins that have to be delicately removed before eating.

Titanium meanwhile, although abundant in the earth’s crust, is horrendously reluctant to submit human efforts to turn it into a bicycle frame. From extraction, to final welding and finishing, titanium is fraught with very complex processes that are as expensive as they are essential. One slip, omission on behalf of the mill, machinist, welder or finisher or the slightest contamination of Oxygen, nitrogen, and hydrocarbon (i.e. human fingertips) at the wrong time and the frame will almost certainly fail at some point.

Hence most bike companies don't do titanium. And of those that do, most do it badly.

So Why Bother With Titanium?

If titanium is so difficult to extract, machine and fabricate why on earth would we bother? In two words – ‘Fatigue Endurance’ – how many times a load has to be applied to a material before it fails. For all other materials that we commonly make bicycle frames from, there is a well defined and documented fatigue failure levels based on cyclical load tolerance. For titanium however the tolerance to cyclical load is infinite. This is a huge advantage both in terms of safety and for ride quality. It means that as long as the tube spec and frame design is well executed a bicycle will offer exceptional comfort, performance and ride the same in its first mile as its millionth!

Titanium Bikes Review: Potential V’s Reality

So what are the best titanium bicycles?

The reality is, unfortunately, that we hear of as many titanium bikes breaking as carbon. Why? Because titanium is impossible to make cheaply and most bikes are sourced from anonymous factories in the far-east where it is impossible to monitor design and construction methods.

With that in mind, here are some questions you may want to posit before for buying titanium:

- Provenance is everything - Ask the builder where the tubing is milled and machined prior to welding?

- You will also want to know why they buy from that particular mill. You will want to ask what titanium grade they use and why and where. i.e. is it aerospace grade 3Al-2.5V or something else?

- Do they butt they their tubing or is it plain or straight-gauge? If so are the tubes are butted internally or externally and are these processes completed in-house or sub-contracted?

- You will want to know the name and experience level of the person who is going to weld your frame.

- Are they titanium specialists or is it another string to their bow? If it is the latter then consider a company who make it their life’s work making your bike for life.

Is All Titanium Equal?

Unhelpfully no. There are three main categories:

- CP or Commercially Pure – not suitable for making bicycle frames – it is neither stiff nor strong enough. To be avoided!

- 3AL-2.5V Alloy – consisting of 94.5% ti, 3% aluminium and 2.5% vanadium – best suited to building bicycle frames because of optimal, strength, fatigue endurance, corrosion-resistance and workability. But not all 3AL-2.5V is itself equal (as we will find later).

- 6AL-4V Alloy - An alloy of 6% aluminum, 4% vanadium and 90% ti. An exceptionally hard material that is useful for making drop-outs etc but difficult to make into a complete bicycle frame.

Not All 3AL-2.5V is Equal. This is becoming a minefield…

There are three main grades of 3-2.5 available and essentially you want the best one for your bike, and that means - 3-2.5 AMS grade 105 (Aerospace Material Specifications) This provides the designer and builder the greatest freedom of expression with the ultimate raw materials with the most exceptional tolerances. But this material is only available to titanium specialists as it has to be pre-purchased in large quantities.

The lesser grades are Sports and Scrap Grades of 3AL-2.5V. Both are inferior because they have fewer processing steps to cut costs, which affects the performance of the material both in construction and final ride and durability.

Essentially you cannot make a great titanium frame without great ingredients, in the same way that you cannot make a fantastic wine without exceptional grapes and vines.

Seven Titanium – The Lightest Touch

Seven stand for so many things but they have an unrivalled industry heritage with titanium. They have been involved in every significant titanium advance and intellectual step-change since 1987. We have bike fitting and custom builds in our blood and we work with Seven because titanium is embedded in their DNA. In terms of their work ethos they are obsessed with ‘purity’. They rely on a base material that even exceeds AMS Grade. Thereafter, they carefully work the material in an obsessive way to preserve the material’s integrity and purity. Seven refuse to embark on any finishing action or process they feel will weaken the titanium’s properties. In all the years we have worked with Seven, and the hundreds of frames that we have designed and made together, we have never had a material failure of any kind. Not one. Download Seven’s Titanium Manifesto which includes some great photos of the titanium frame manufacturing process and more insights into this fabulous material.

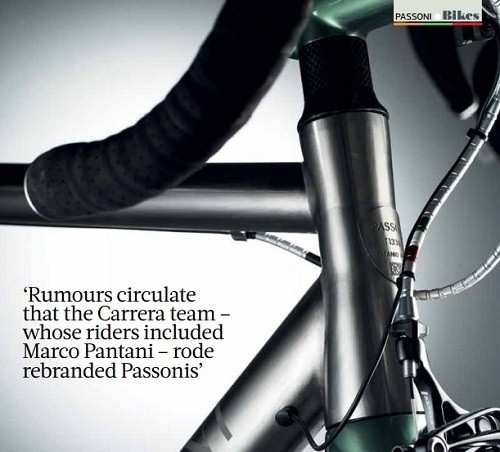

Passoni

Father and son Luciano and Luca Passoni exhibited their first ever titanium bicycle in 1989 atEICA (Esposizione Internazionale Ciclo Motociclo e Accessori) show in Milan. Now Passoni produce around 400 frames per year. All frames are custom and all made from the finest Italian titanium stock. Passoni’s twin obsessions are build integrity and beauty. All their frames finish production with a 30 hour polishing and sanding process that removes all of the visible weld to leave a bewildering seamless titanium form. This is enough to make otherwise responsible adults lose control and covet a Passoni like no other possession they will ever own.